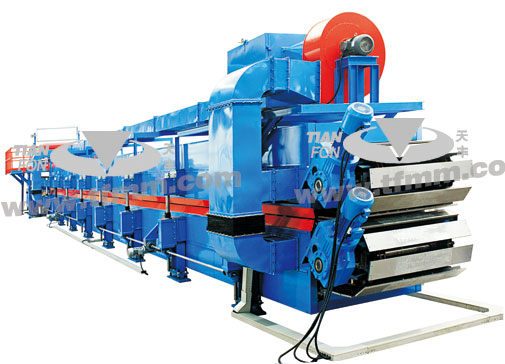

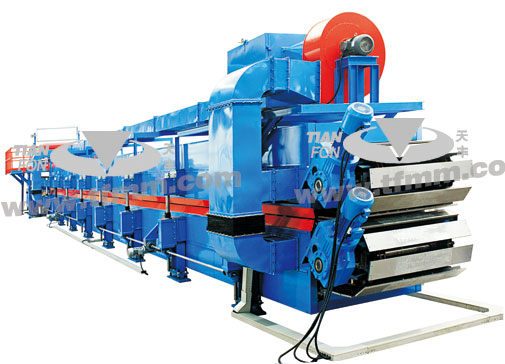

Uncoiling area includes two sets uncoilers, Roller Conveyors, sending device, cutting device, filming device etc.

Roll forming area:

There are upper and lower roll forming machine and quick change system, it is possible to produce various profiles to meet diversified demands.

Foaming area:

Foaming area composed of High pressure PU foaming machine , casting machine and double crawler etc.PU provided foaming machine with electrical metering mechanism, automatic coil provided system to insure the material mixed according to ratio, spraying equally, the double crawler with accurate temperature control system and safety foaming processing to assure foaming equally and stable.

Saw cutting area:

Saw cutting area includes saw and milling machine to finish scale cut off.

Stacking and packing

Stacking and packing consists of fast transiting conveyer, automatic turn-over, stacking and packing system etc. it is easy to assure the production on line and avoid damage and losing during transiting to improve the production efficiency.

Automatic control system:

The production adopts Siemens control system, Humanized interface easy to operate, monitor and adjust the parameters to assure production running stable and effectively.

The production line is designed after study and research abroad advanced technology, which provided with international advanced lever.

|

COVER WIDTH(mm) |

COIL WIDTH(mm) |

WAVE HEIGHT(mm) |

WAVE LENGTH(mm) |

USAGE |

|

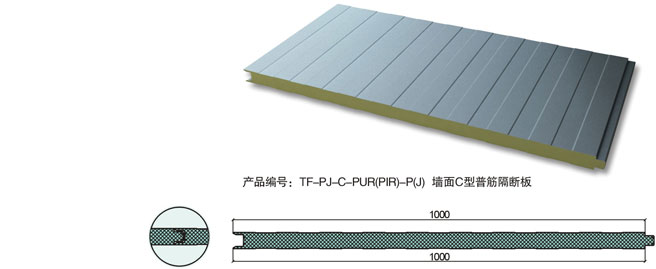

950 |

1000

|

5

|

95

|

PU PANEL

|

|

COVER WIDTH(mm) |

COIL WIDTH(mm) |

WAVE HEIGHT(mm) |

WAVE LENGTH(mm) |

USAGE |

|

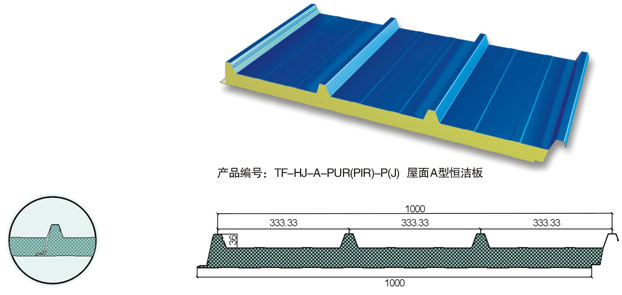

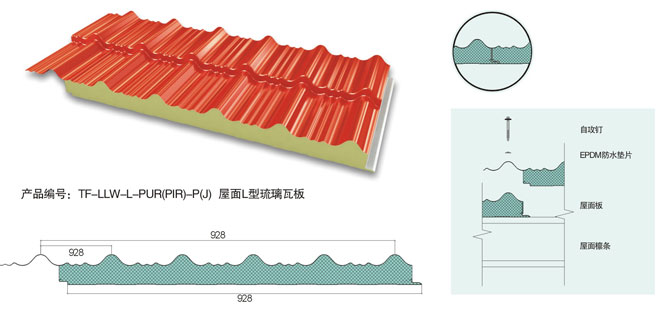

1000 |

1065

|

50

|

452

|

PU PANEL

|

|

COVER WIDTH(mm) |

COIL WIDTH(mm) |

WAVE HEIGHT(mm) |

WAVE LENGTH(mm) |

USAGE |

|

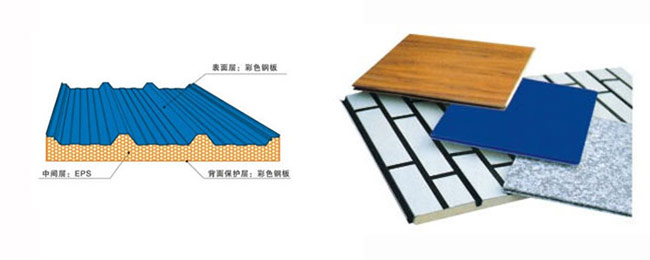

950 |

1250

|

42

|

317

|

PU PANEL

|

|

COVER WIDTH(mm) |

COIL WIDTH(mm) |

WAVE HEIGHT(mm) |

WAVE LENGTH(mm) |

USAGE |

|

1000 |

1050

|

40

|

60

|

PU PANEL

|

|

COVER WIDTH(mm) |

COIL WIDTH(mm) |

WAVE HEIGHT(mm) |

WAVE LENGTH(mm) |

USAGE |

|

1000 |

1200

|

37

|

250

|

PU PANEL

|