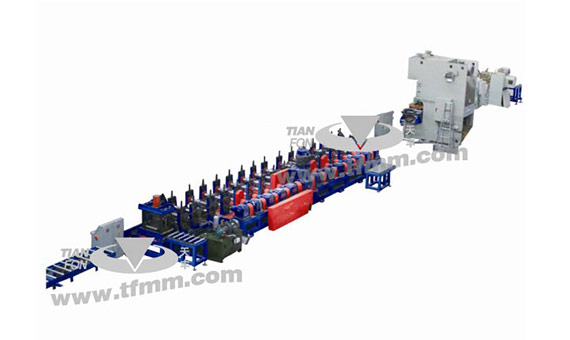

TF building, storage use C60-250 steel plank roll forming line

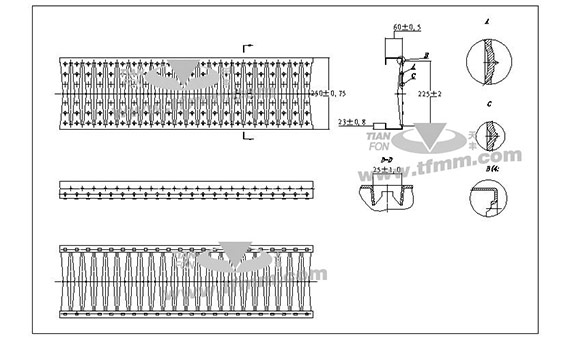

TF building, storage use C60-250 steel plank roll forming line main specification

1) Thickness: 2.0mm

2) Width of Coil: About 406mm

3) Material: Q235

4) Yield Stress: ≤235MPa

5) Forming Step: 16 steps

6) Material of Roller: GCr15,

Hardness HRC58-62, Chroming

7) Produce Speed:About 5-6m/min

8) Tolerance:from the end 300mm

Open in tolerance ±2mm

9) Power:

Three-phase ac power:380V(±10%),50HZ

10) Environment temperature:-10℃~40℃,

Relative humidity:≤90%(25℃)No coagulate frost

11) Floor space: 31m*3.5m

2 、TF building, storage use C60-250 steel plank roll forming line process flow and equipment composition

Un-coiling--leveling--servo-feeding—punching—forming—moving cut—run-out

3、TF building, storage use C60-250 steel plank roll forming line equipment composition

a) Un-coiler one set

b) Levele one set

c) Servo-feeder one set

d) Punch Device one set

e) Forming Machine one set

f) Moving Cutter one set

g) Run out Table one set

h) Hydraulic System one set

i) PLC Control System one set

The steel plank uses include:

1. Construction Sites

2. Storage shelves

3. Helicopter Landing Pads

4. Irrigation Tracks

5. Launches and boat ramp extensions

6.Corrals and chutes for livestock

7. Warehouse flooring

8. Mobile home moving

9. RV tracks or storage areas

10. Storage platforms for heavy equipment, supplies or runways.