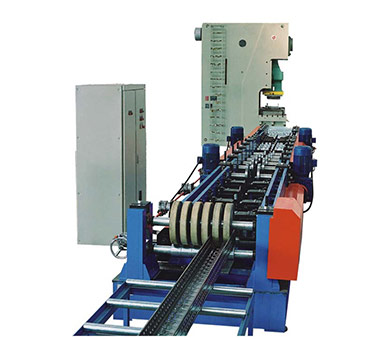

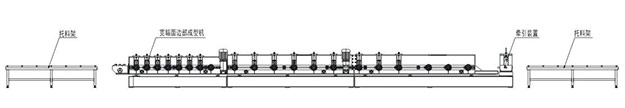

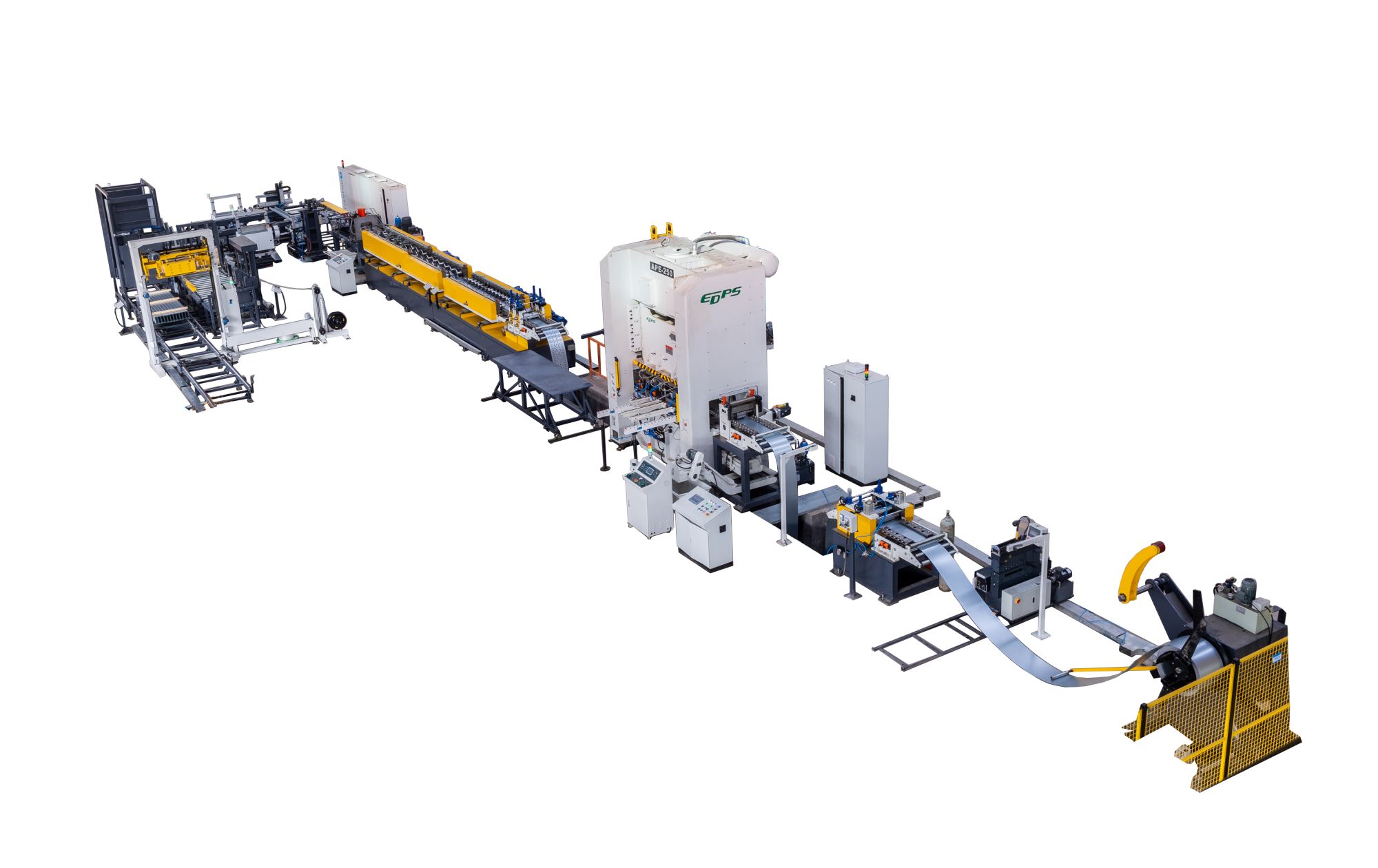

Uncoiling –leveling- Looping—Feeding—punching —Roll forming—Cutting –Discharging

2. Cable bridge roll former Components

(1) Un-coiler 1 set

(2) Leveling machine 1 set

(3) Feeding device 1 set

(4) Mechanical punching machine 1 set

(5) Roll forming machine 1 set

(6) Cutting device 1 set

(7) Run out of table 1 set

(8) PLC control system 1 set

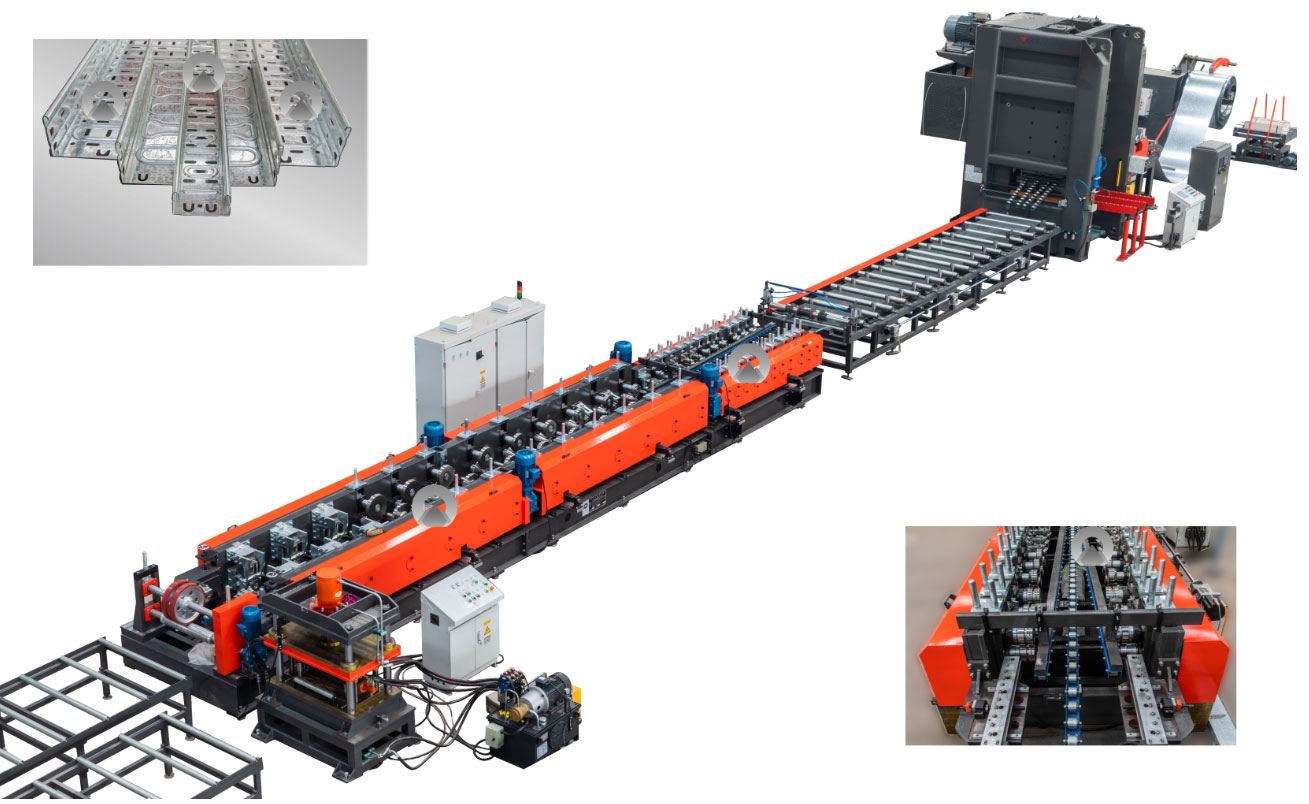

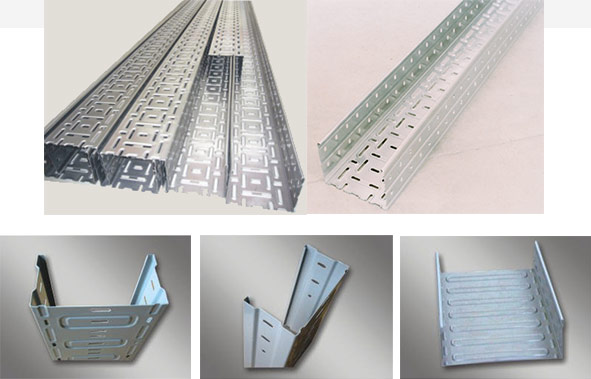

cable bridge roll forming line

HIGH SPEED ROLL FORMING LINE FOR CABLE TRAY WITH STACKER

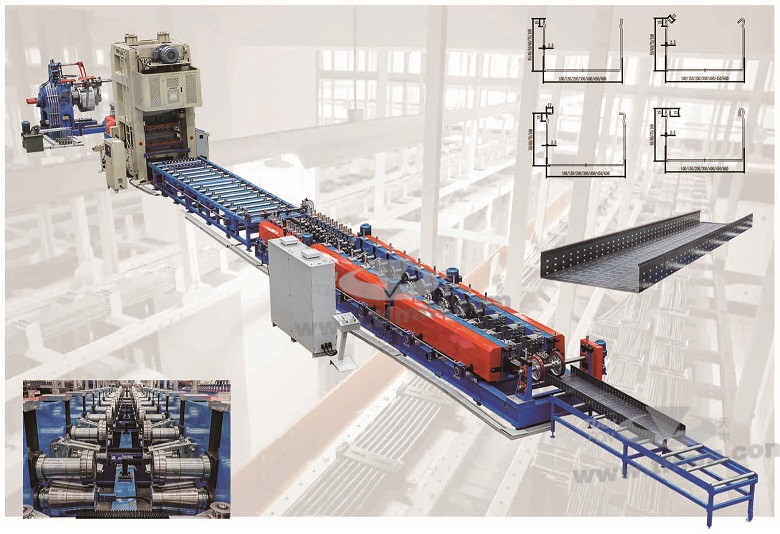

cable bridge roll forming line

3 Roll forming machine Structure and function:

( 1). Double cantilever gear drives, the producing width of machine is adjust continually, it is possible to change the width and height.

( 2). Rolling stations is 20 steps ,the main machine consists of AC motor,reducer,high precision liner rail, transmission box on left and right, horizontal adjustment system and rolling moulds. The machine base and transmission adopts welding structure , with hardness treatment, the material of roller is 45# steel.

( 3). The roll forming craft is made by the special Germany cold roll forming program COPRA; the craft is also made the FEA analysis and check. The structure of the rollers is combined, so the line speed difference and resisting force of roll forming is small. The sheet is easy to feed. All these assure the accuracy and stable of the roll forming.

|

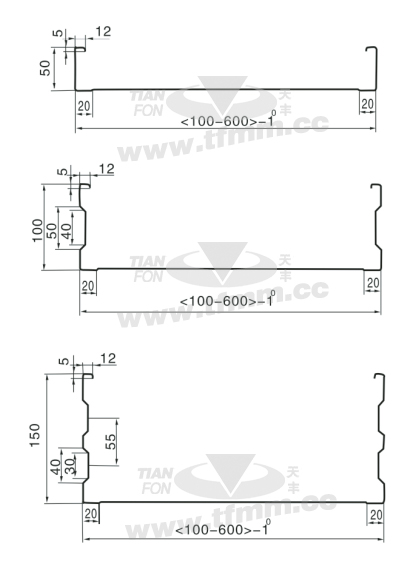

Adjusted Range

|

|

|

Model |

Size |

|

Height |

50/100/150 |

|

Width |

100/200/300/400/500/600 |

|

CABLE TRAY

|

||||

|

MODEL |

SECTION SIZE(mm) |

|||

|

W |

A |

B |

C |

|

|

I |

100 |

15 |

35 |

75 |

|

II |

200 |

15 |

35 |

75 |

|

III |

300 |

20 |

50 |

100 |

|

IV |

400 |

20 |

50 |

100 |

|

V |

500 |

60 |

60 |

150 |

|

VI |

600 |

60 |

60 |

150 |