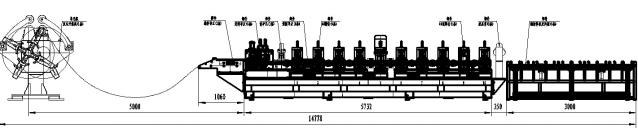

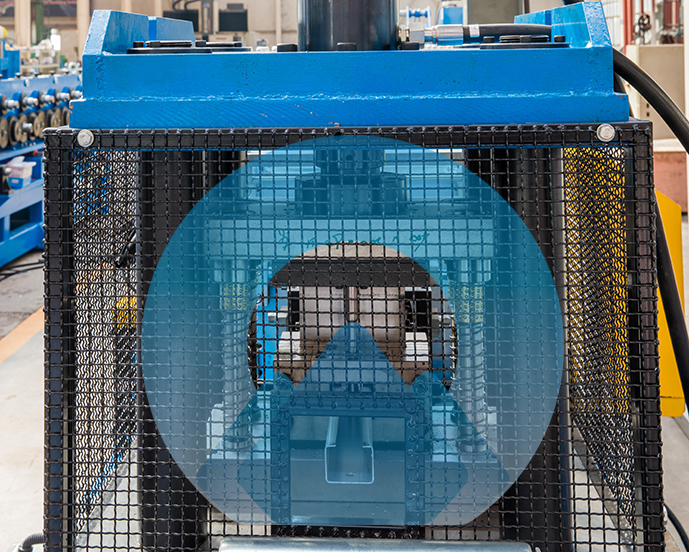

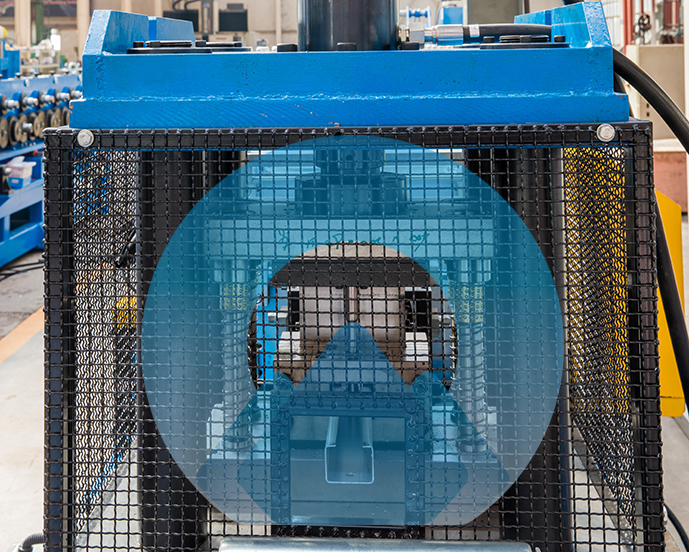

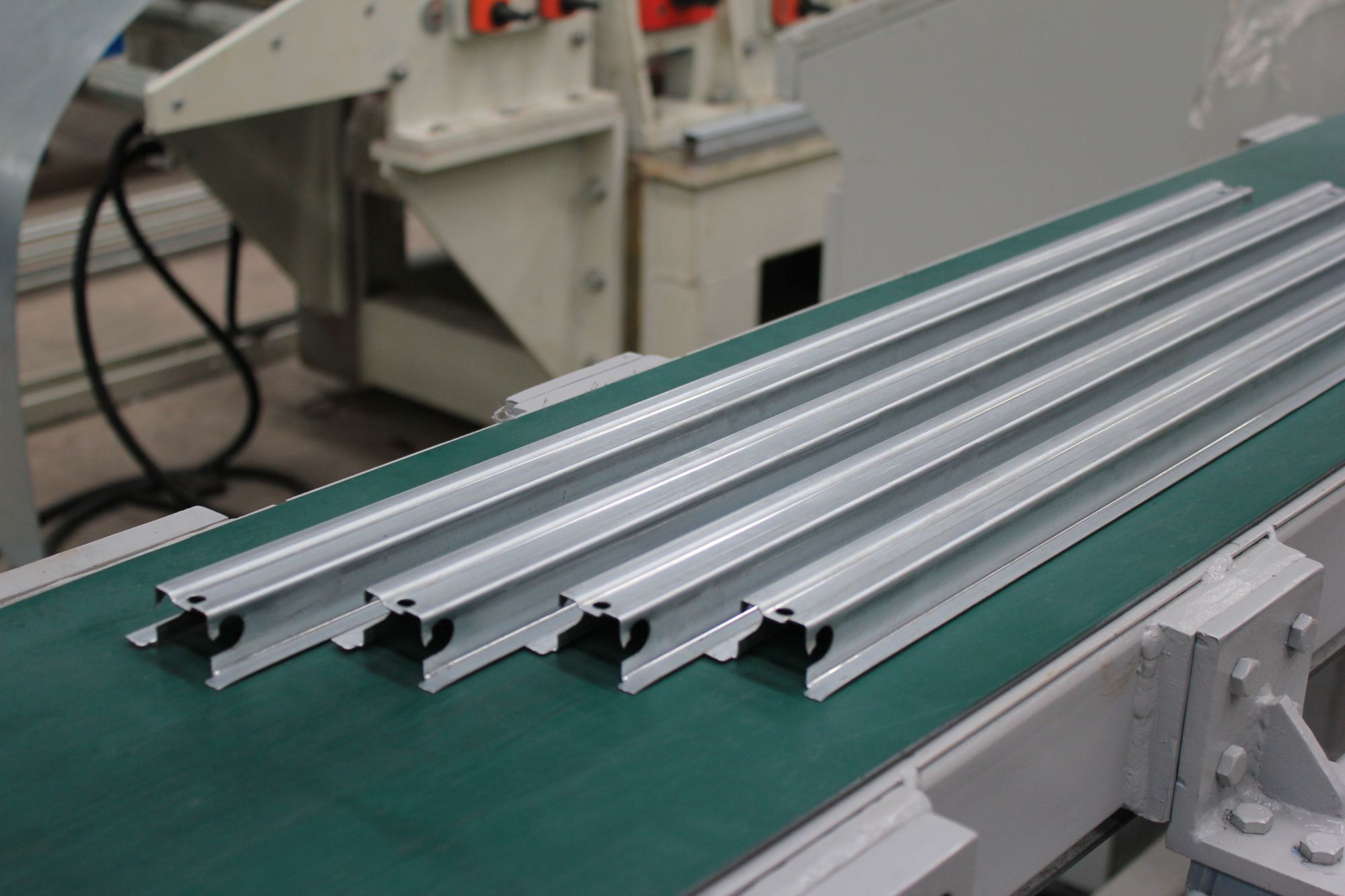

1. The roller frame adopts the overall structure and is finished. The distance between the upper and lower rollers is adjusted by the eccentric sleeve on the roller shaft. The locking device guarantees that the equipment is undefined. Upper and lower roller bearings are lubricated.

2. Foundry archway is installed on the frame, and the distance is adjusted by rotating the screw. The molding machine uses a three-phase AC motor to drive the main reducer, which is installed in the middle of the molding machine. The transmission box is driven to drive in series, and the power is transmitted to the upper and lower shafts of the forming unit through a clutch. The necessary passes are equipped with up and down synchronization gears.

Its transmission mode: main motor → gear reducer → transmission bevel gear box → clutch → roller shaft under the arch.

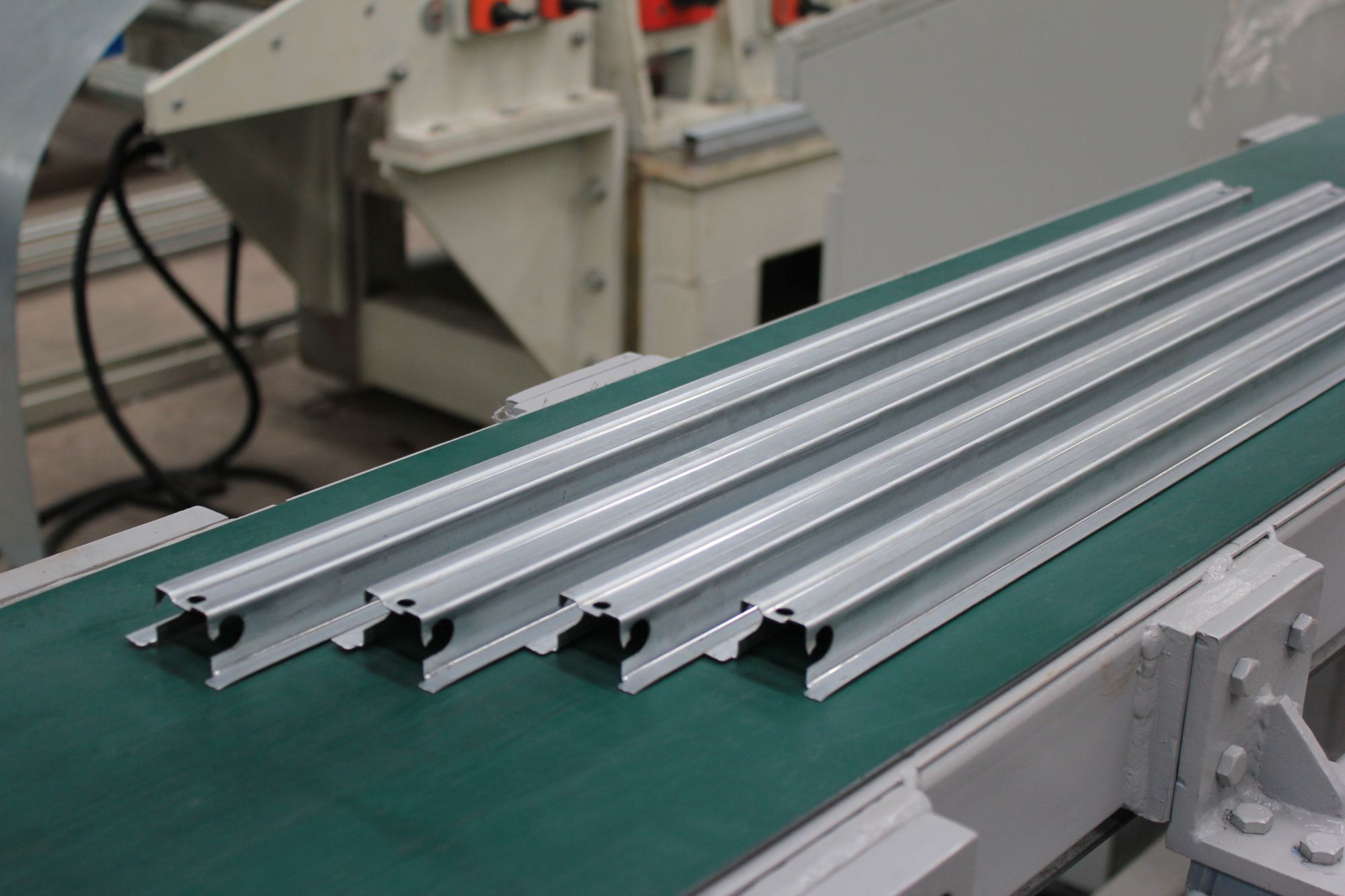

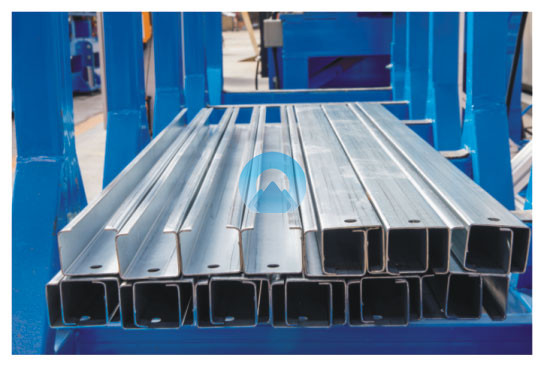

The roller frame adopts a torii structure with high rigidity; the positioning hole of the lower roller shaft of the torii uses a fixed circular hole for positioning, and the positioning of the upper roller shaft uses a chute. The rollers are made of high-quality steel and finished to ensure assembly accuracy. The strength is sufficient. The bearing is installed at the shaft end and is placed in the bearing seat. The bearing is fixed on the torii slideway, and the clearance between the upper and lower rollers is adjusted by a screw.